In the realm of mass production, output reigns supreme. To achieve these lofty goals, manufacturers turn to high-speed injection molding machines. These sophisticated pieces of equipment are capable of producing a massive volume of parts in a minimal timeframe, making them ideal for industries with extensive demand.

The process involves injecting molten plastic into a mold cavity at lightning speeds, creating intricate and robust components. This advancement has revolutionized manufacturing by enhancing production processes and cutting down lead times.

One of the primary advantages of high-speed injection molding machines is their ability to maintain a stable level of quality across every produced part. This dependability is crucial for industries where precision is paramount.

Furthermore, these machines offer versatility in terms of the plastics they can process and the intricacy of the parts they can create. From simple components to complex devices, high-speed injection molding machines can handle a broad range of applications.

Precision Plastic Injection Molding: A Comprehensive Guide

Precision plastic injection molding presents itself as a versatile manufacturing process utilized to create high-quality products from thermoplastic materials. This process encompasses heating the plastic material until it assumes a molten state, then pumping it into a precisely engineered mold cavity. As the molten plastic solidifies, it forms the desired shape of the mold, resulting in intricate and accurate components.

- Employing advanced technologies and materials allows for the production of parts with exceptional dimensional accuracy, surface finish, and strength.

- Ideal for a wide range of industries, precision plastic injection molding finds applications in diverse fields such as automotive, electronics, medical devices, and consumer goods.

Additionally, this article will explore the diverse stages involved in precision plastic injection molding, including mold design, material selection, processing parameters, and quality control measures.

Fine-tuning Injection Molding Processes for Efficiency and Quality

Injection molding is a versatile manufacturing process widely used in producing diverse products. To achieve optimal efficiency and quality, it's crucial to continuously improve the injection molding process. This entails careful attention of various parameters, including the type of material used, mold design, processing conditions, and quality control techniques.

By adopting best practices in each of these areas, manufacturers can greatly lower cycle times, enhance product consistency, and minimize defects.

Here are some key methods for optimizing injection molding processes:

- Performing thorough process simulations to identify potential issues before mold fabrication.

- Optimizing mold design to facilitate efficient flow and reduce cooling durations.

- Selecting the appropriate injection parameters based on material properties and product specifications.

- Integrating real-time process monitoring systems to pinpoint irregularities.

- Developing rigorous quality control procedures to meet quality standards.

Through continuous improvement and a commitment to excellence, manufacturers can harness the full potential of website injection molding processes to produce high-quality products efficiently and reliably.

Injection Molding Machine Design Considerations

Designing an injection molding machine is a intricate procedure that demands careful consideration of numerous factors. A skilled engineer must analyze the specific requirements of the mold being produced, as well as the polymer being used. Key design parameters include the machine's capacity, clamping force, temperature control, injection volume, and cycle time.

The choice of appropriate mold materials, such as steel or aluminum, is also critical for ensuring product quality and longevity. Additionally, the machine's structure must accommodate the necessary auxiliary systems, including cooling circuits, material handling devices, and automation features.

Identifying Common Injection Molding Defects

Injection molding is a versatile manufacturing process but it's not immune to defects. Understanding these common problems and their causes can help you optimize your production process so that high-quality parts.

Here are some typical injection molding defects you may encounter:

* **Short Shots:** Taking place when the molten plastic doesn't completely fill the mold cavity, often leading to an incomplete part. This can stem from insufficient melt flow, improper machine settings, or a clogged nozzle.

* **Flash:** Extra plastic that flows out of the mold cavity across the molding process. This can stem from incorrect mold design, high injection pressure, or excessive heat.

* **Sink Marks:** Indentations on the part surface which occur because uneven cooling and shrinkage of the plastic.

* **Warpage:** Distortion or deformation of the molded part after it cools. This can depend on improper mold design, uneven heating, or rapid cooling rates.

* **Voids:** Air gaps within the plastic part that occur during the molding process as a result of trapped air or insufficient melt flow.

Properly pinpointing these defects can be crucial for implementing effective solutions. Through analyzing the defect, its location, and your underlying causes, you can modify your molding process in order to produce high-quality parts consistently.

Automated Injection Molding Systems for Industry 4.0

In the rapidly evolving landscape of Production 4.0, automated injection molding systems are emerging as crucial components for enhancing Productivity. These sophisticated systems leverage cutting-edge technologies such as Internet of Things (IoT) to optimize the entire molding process, from material Handling to part Assurance. By integrating Robotics, these systems enable Businesses to achieve Improved Precision in product quality, reduce Downtime, and Optimize production workflows.

Furthermore, automated injection molding systems contribute to data-driven decision-making by providing real-time Feedback on process parameters. This allows for Fine-Tuning of the molding process, leading to Reduced Costs. As Industry 4.0 continues to reshape Manufacturing, automated injection molding systems are poised to play a pivotal role in driving Progress and shaping the future of manufacturing.

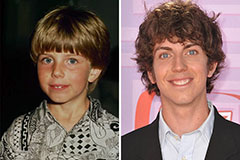

Taran Noah Smith Then & Now!

Taran Noah Smith Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Robin McGraw Then & Now!

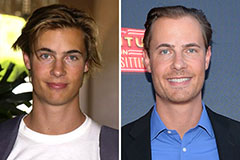

Robin McGraw Then & Now! Ryan Phillippe Then & Now!

Ryan Phillippe Then & Now!